3D printing has come a long way from its early days of creating simple prototypes. Now, it’s revolutionizing industries from healthcare to fashion. Every time I jump into the latest advancements, I’m amazed at how this technology keeps pushing boundaries and opening up new possibilities.

In this text, I’ll discuss some of the most exciting trends and innovations in 3D printing. We’ll explore how it’s transforming manufacturing, the creative ways it’s being used, and what the future might hold. Whether you’re a tech enthusiast or just curious about the latest 3D printing, there’s something here for everyone.

Bambu Lab’s Commitment in 3D Printing Innovation

Bambu Lab dedicates itself to making high-quality technology accessible to everyone. It uses advanced knowledge and innovative production methods. I remember visiting its facility and being amazed by its state-of-the-art 3D Drucker.

Key Innovations

Eco-Friendly Designs

Bambu Lab’s 3D printers are designed to reduce the carbon footprint. They incorporate recyclable materials and energy-efficient components.

Advanced Production Methods

Leveraging cutting-edge techniques, Bambu Lab ensures precise, reliable results in its 3D printing process, pushing industry standards forward.

Accessibility

Their commitment extends to making technology affordable, allowing hobbyists and professionals to explore 3D printing’s potential.

- Sustainability: Continued focus on eco-friendly innovations.

- Technological Advancements: Anticipation of more sophisticated 3D printers.

- Global Reach: Expanding access to emerging markets.

Bambu Lab’s dedication to innovation in 3D printing positions them as a leader in the industry.

Emerging Trends in 3D Printing

Advanced Materials

Advanced materials push the boundaries of what we can create in 3D printing. I once experimented with flex materials, crafting a comfortable and stable T-watch band. This hands-on experience highlighted how these materials transform product quality and functionality.

- Composite Filaments: Combine materials to enhance strength and durability.

- Biodegradable Polymers: Offer eco-friendly alternatives without compromising performance.

- Metal Powders: Enable the creation of strong, heat-resistant parts.

These materials improve the end products and broaden the applications of 3D printing in various industries.

High-Speed Printing

High-speed 3D printing is revolutionizing production times. New methods like Continuous Liquid Interface Production (CLIP) and Multi Jet Fusion are making it faster. These innovations cut layers quickly. My first time using a high-speed 3D drucker, I went from hours to minutes for prints. That opened my eyes.

- Continuous Liquid Interface Production (CLIP): Uses a liquid resin to reduce build times significantly.

- Multi Jet Fusion (MJF): Employs fine powder and thermal fusing to speed up printing.

Manufacturers benefit from increased efficiency and cost savings.

Multi-Material Printing

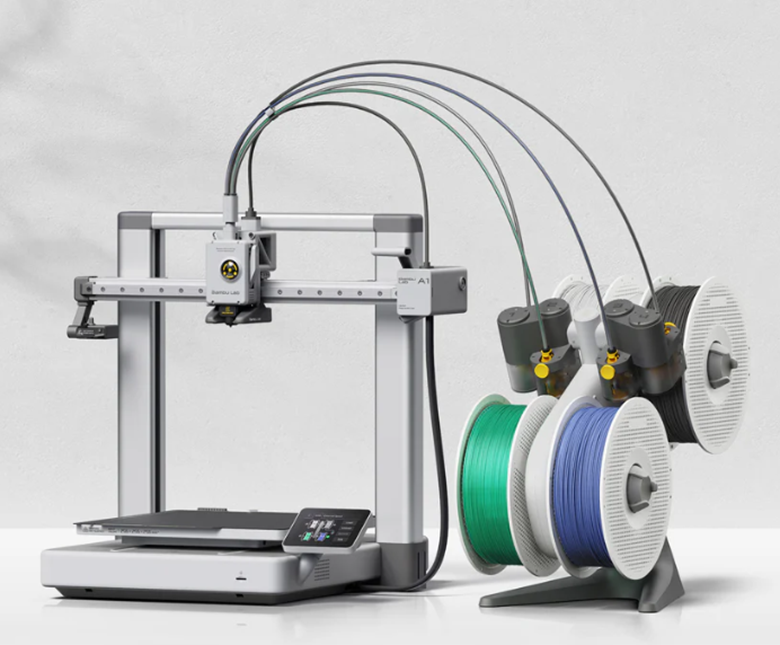

Emerging technologies now enable printers to handle multiple materials within a single build, transforming the possibilities for creating objects with complex structures and varying properties.

AMS (Automatic Material System)

The AMS revolutionizes 3D printing by automating material changes during printing. It crucially reduces manual intervention, boosting productivity. The seamless transition between materials was impressive when I first used AMS in my 3D Drucker. The system automatically switches filaments based on pre-determined print sequences, improving workflow efficiency. AMS benefits industries by minimizing downtime and material waste producing higher quality prints with less effort.

Integration of Multiple Filaments in a Single Print

Printers can now blend several filaments within the same project. This innovation enables the production of detailed, functionally varied parts without assembly. For instance, combining flexible and rigid filaments creates objects with both length and flexibility in targeted areas. Achieving this level of detail enhances prototypes and end-use products, making it a game-changer for the automotive, healthcare, and consumer goods industries.

Hybrid Printing Technologies

Hybrid printing technologies merge additive and subtractive manufacturing, leveraging both strengths. They offer unmatched precision by combining 3D printing and CNC machining in one machine. This integration results in parts with intricate features and superior surface finishes. Manufacturing complex parts rapidly and accurately becomes feasible, reducing lead times and costs. Hybrid technologies are particularly useful for producing gear mechanisms and medical devices.

AI and Machine Learning

AI and machine learning significantly impact 3D printing advancements, making processes smarter and more efficient. I remember using a 3D Drucker and noticing the tedious trial-and-error for perfect prints. With AI integration, printers now auto-adjust settings, drastically improving quality.

- Enhanced Print Quality: AI algorithms analyze print data to minimize errors and optimize settings.

- Predictive Maintenance: Machine learning predicts machine failures, reducing downtime and maintenance costs.

- Automated Design: AI helps generate optimized designs that are often too complex for traditional software.

These innovations improve the 3D printing experience, making it friendlier and more productive.

Large-Scale 3D Printing

Large-scale 3D printing has revolutionized manufacturing on an industrial level. My firsthand experience with a large-scale 3D Drucker in a workshop demonstrated how this technology can produce larger parts efficiently. Large-format printers handle greater volumes, from aerospace components to architectural elements, without sacrificing precision.

Key Benefits

- Efficiency: Larger build volumes reduce assembly time.

- Cost Savings: Producing bigger parts in a single run lowers material waste.

- Versatility: The ability to print varied dimensions enhances project flexibility.

Metal 3D Printing

Metal 3D printing sky has rocketed in recent years. Industrial applications have expanded rapidly, from aerospace to healthcare. For example, I once saw a demonstration of a 3D druprinterinting a titanium implant, showcasing its precision and strength.

Benefits of Metal 3D Printing

- Durability: Printed metal parts often exhibit high strength.

- Customization: Unique designs and complex geometries are achievable.

- Efficiency: Reduces material waste compared to traditional methods.

- Speed: Prototyping and production are quicker.

Conclusion

The ever-evolving landscape of 3D printing continues to astound and inspire. From advanced materials like biodegradable polymers and metal powders to high-speed and multi-material printing capabilities, the innovations are transforming how we design and manufacture. Companies like Bambu Lab are in charge of eco-friendly, high-quality technology accessible to all. As we embrace these advancements, we unlock new possibilities across industries, from healthcare to aerospace, creating a future where the limits of our imagination are the only boundaries. Dive into this exciting world and see how 3D printing shapes the future, one layer at a time!

Buy Me A Coffee

The Havok Journal seeks to serve as a voice of the Veteran and First Responder communities through a focus on current affairs and articles of interest to the public in general, and the veteran community in particular. We strive to offer timely, current, and informative content, with the occasional piece focused on entertainment. We are continually expanding and striving to improve the readers’ experience.

© 2025 The Havok Journal

The Havok Journal welcomes re-posting of our original content as long as it is done in compliance with our Terms of Use.