In the ever-evolving landscape of industrial manufacturing, innovation plays a pivotal role in ensuring products meet the demanding requirements of modern industries. Plastic molding, a cornerstone of manufacturing, has undergone significant advancements to address complex industrial applications. With its ability to deliver high precision, durability, and efficiency, innovative plastic molding techniques are revolutionizing sectors such as automotive, aerospace, healthcare, and consumer electronics.

This blog explores the transformative impact of advanced plastic molding processes, shedding light on the technologies, benefits, and applications that make them indispensable in today’s industrial ecosystem.

The Evolution of Plastic Molding Technologies

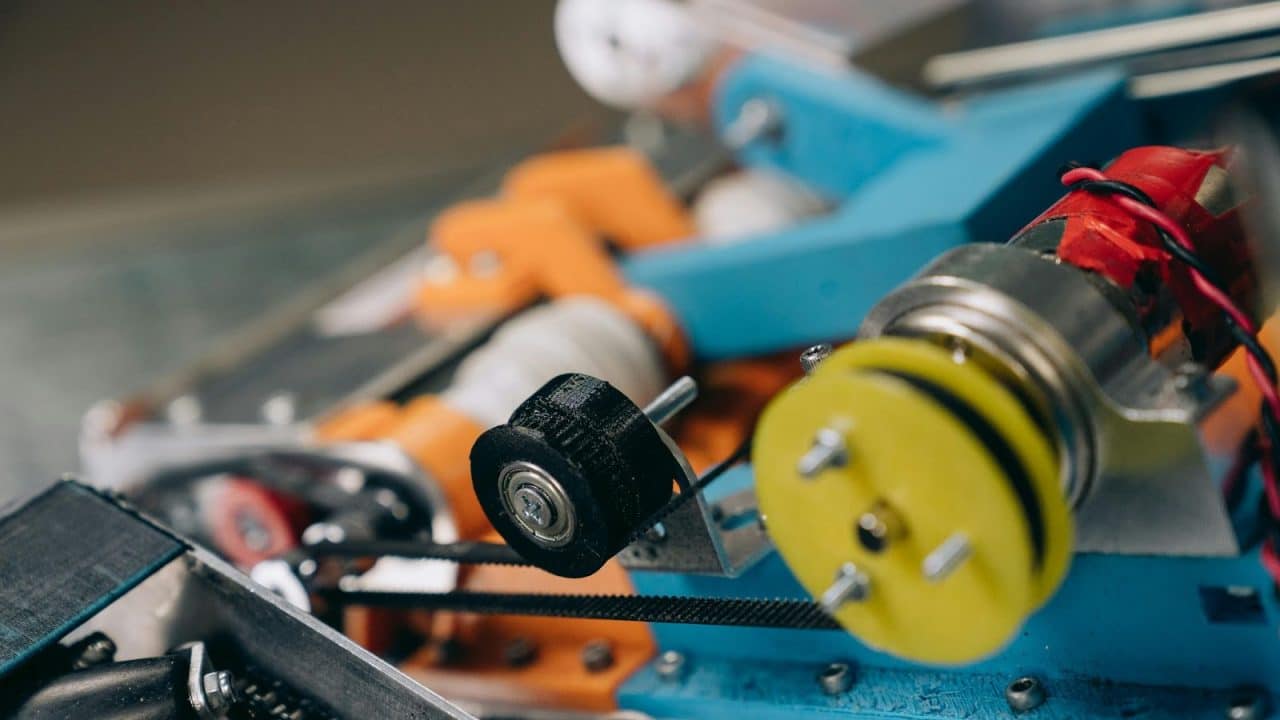

Plastic molding has come a long way from its traditional methods. Initially, processes like compression molding and injection molding dominated the industry, offering manufacturers a reliable way to produce large quantities of components. You can find out more about plastic injection molding services and how they are transforming modern manufacturing processes. As industries began demanding more intricate and high-performance parts, the need for innovation has become apparent.

Below are some of the modern plastic molding technologies that incorporate cutting-edge advancements:

- 3D Printing and Additive Manufacturing:

- 3D printing allows for rapid prototyping and production of complex geometries that were previously unattainable with conventional methods.

- It reduces material wastage and speeds up product development cycles.

- Micro-Molding:

- Ideal for producing ultra-small parts, micro-molding has become essential in industries like healthcare, where precision is critical for medical devices.

- This process accommodates intricate designs with tolerances in the micrometer range.

- Gas-Assisted Injection Molding:

- This technique uses pressurized gas to create hollow sections within molded parts, reducing weight while maintaining structural integrity.

- Widely used in the automotive and furniture industries, it enhances product aesthetics and functionality.

- Multi-Material Molding:

- By integrating multiple materials into a single component, this method enables manufacturers to create parts with varied properties, such as hardness and flexibility.

- This is particularly useful in consumer electronics and automotive applications.

Benefits of Innovative Plastic Molding

The evolution of plastic molding has unlocked numerous benefits, making it the go-to solution for complex industrial applications:

- Design Flexibility: Advanced molding techniques enable the production of intricate and customized designs that meet specific application requirements.

- Cost Efficiency: Automation and precision reduce material wastage and labor costs, ensuring economical large-scale production.

- Enhanced Performance: New materials and techniques deliver parts with superior mechanical properties, such as higher strength-to-weight ratios and improved thermal resistance.

- Eco-Friendly Solutions: Many innovative molding processes focus on sustainability, incorporating recycled materials and minimizing energy consumption.

- Speed to Market: Rapid prototyping and streamlined production processes accelerate the transition from concept to market-ready products.

Applications in Complex Industrial Sectors

Automotive Industry

The automotive sector has embraced innovative plastic molding to meet its stringent demands for lightweight, durable, and aesthetically appealing components. Examples include:

- Dashboard Panels and Trim: Gas-assisted injection molding creates lightweight yet rigid components.

- Under-the-Hood Applications: High-performance thermoplastics withstand extreme temperatures and chemical exposure.

- Safety Systems: Precision-molded components for airbags and seatbelt mechanisms enhance reliability.

Aerospace Sector

In aerospace, where weight reduction and performance are critical, advanced plastic molding plays a vital role:

- Structural Components: Lightweight composite materials reduce fuel consumption and emissions.

- Cabin Interiors: Multi-material molding creates ergonomic and visually appealing cabin parts.

- High-Precision Parts: Micro-molding ensures accuracy for small components in avionics systems.

Healthcare and Medical Devices

The healthcare industry relies on innovative plastic molding for its stringent quality and safety standards:

- Medical Equipment: Micro-molding produces components for minimally invasive surgical tools and diagnostic devices.

- Consumables: Single-use items like syringes and vials are manufactured with high precision and sterility.

- Wearable Devices: Multi-material molding integrates electronics into flexible plastics for patient monitoring systems.

Consumer Electronics

The demand for sleek, compact, and multi-functional devices has driven the adoption of advanced plastic molding in electronics:

- Casings and Enclosures: Multi-material molding combines rigidity and aesthetics.

- Connectors and Switches: Micro-molding ensures durability and precision for small electrical components.

- Cooling Systems: Thermally conductive plastics improve heat dissipation in electronic devices.

Challenges and Future Prospects

While the benefits are undeniable, innovative plastic molding is not without challenges. Some of the key hurdles include:

- Material Limitations: Developing new polymers that meet diverse industrial requirements remains a significant focus area.

- High Initial Costs: Advanced machinery and tooling require substantial upfront investment.

- Environmental Concerns: Despite advancements, addressing plastic waste and ensuring recyclability are ongoing challenges.

Looking ahead, the future of plastic molding is promising. Emerging trends include:

- Smart Molding Technologies: Integration of AI and IoT for real-time monitoring and optimization of the molding process.

- Biodegradable Plastics: Development of eco-friendly materials to reduce environmental impact.

- Hybrid Manufacturing: Combining traditional molding with additive manufacturing for unparalleled design freedom.

Innovative plastic molding has become an integral part of modern industrial manufacturing, offering unparalleled versatility and efficiency. From automotive and aerospace to healthcare and consumer electronics, its applications are vast and varied. By embracing cutting-edge technologies and sustainable practices, the industry continues to push the boundaries of what is possible. Businesses that leverage these advancements will not only gain a competitive edge but also contribute to a more sustainable future for all.

Buy Me A Coffee

The Havok Journal seeks to serve as a voice of the Veteran and First Responder communities through a focus on current affairs and articles of interest to the public in general, and the veteran community in particular. We strive to offer timely, current, and informative content, with the occasional piece focused on entertainment. We are continually expanding and striving to improve the readers’ experience.

© 2026 The Havok Journal

The Havok Journal welcomes re-posting of our original content as long as it is done in compliance with our Terms of Use.