When it comes to housing electronic devices, the right enclosure is essential for protection, durability, and performance. Whether you’re working on a personal project, managing an industrial application, or looking for something in between, choosing the right type of electronic enclosure can make a significant difference. With a variety of materials, designs, and protective features available, finding the best fit for your needs may feel overwhelming. This guide will help you understand the different types of electronic enclosures and how to choose the one that suits your specific requirements.

1. Metal Enclosures: Durability and Strength

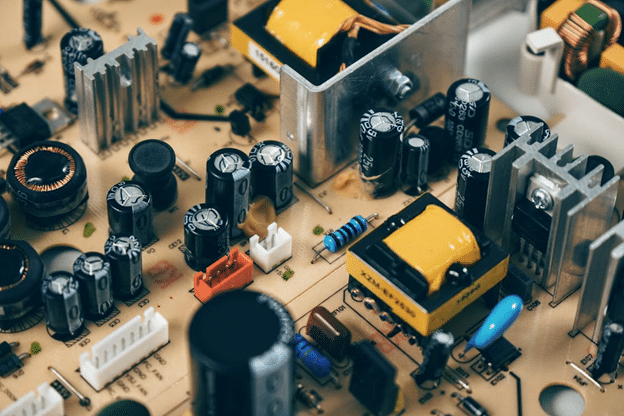

Metal enclosures are known for their durability and strength, making them ideal for protecting sensitive electronics in harsh environments. These enclosures are commonly made from materials such as stainless steel, aluminum, or die-cast metal, each offering different levels of protection and resistance to corrosion.

Stainless steel enclosures, for example, are highly resistant to rust and other corrosive elements, making them a great choice for outdoor applications or environments with high humidity. Aluminum enclosures, on the other hand, offer lightweight protection while maintaining strength, which makes them suitable for portable devices. Metal enclosures are often used in industrial settings, where shielding electronics from electromagnetic interference (EMI) is also crucial.

2. Plastic Enclosures: Lightweight and Versatile

Plastic enclosures are a popular choice for many electronic applications due to their versatility and lightweight nature. Made from materials such as polycarbonate, ABS (Acrylonitrile Butadiene Styrene), and PVC, plastic enclosures offer a cost-effective solution that is easy to customize and mold into various shapes and sizes.

Polycarbonate enclosures, in particular, are known for their impact resistance and UV stability, making them suitable for outdoor use. ABS enclosures, on the other hand, are lightweight and affordable, commonly used in consumer electronics and small-scale projects. One of the key advantages of plastic enclosures is their ability to provide insulation, which protects electronics from electrical interference.

For projects that require customization, plastic enclosures offer a flexible solution without compromising on protection. They are particularly well-suited for indoor applications or environments where heavy-duty protection is not necessary.

3. IP-Rated Enclosures: Water and Dust Protection

If you’re working on a project that requires protection from water, dust, or other environmental factors, it’s important to consider an enclosure with an IP (Ingress Protection) rating. The IP rating system is used to classify the level of protection an enclosure provides against solid particles and liquids. For example, an enclosure with an IP67 rating is dust-tight and can withstand temporary submersion in water.

These enclosures are ideal for outdoor applications, marine equipment, or industrial environments where exposure to moisture or dust is common. By choosing an enclosure with the appropriate IP rating, you can ensure that your electronics remain safe and functional in challenging conditions.

When selecting a water- or dust-resistant enclosure, ensure you are fully aware of the specific rating requirements for your project. In some cases, a higher IP rating may be necessary to meet industry standards or regulatory requirements.

4. Customizable Enclosures: Tailored to Your Specifications

In some cases, off-the-shelf enclosures may not meet the specific needs of your project. That’s where customizable enclosures come in. These enclosures can be modified or designed from scratch to accommodate your electronics, ensuring that the housing perfectly fits your device. Custom enclosures allow you to choose the material, size, shape, and any additional features you may need, such as cutouts for switches, ventilation, or ports.

Companies that specialize in custom enclosures offer a wide range of options, including both plastic and metal varieties. If you’re looking for enclosures with specific features or aesthetics that standard models can’t offer, considering customizable options is the best way to go.

For example, when seeking high-quality customizable enclosures, visiting a trusted supplier like www.budind.com/ provides access to a variety of customizable designs and materials to meet your project’s exact needs. Customization options allow you to modify everything from the size and material to specific cutouts and features, ensuring a perfect fit for your electronics. By working with a reliable provider, you can ensure that the enclosures meet both aesthetic and functional requirements.

5. EMI Shielding Enclosures: Protection from Interference

Electromagnetic interference (EMI) can significantly disrupt the performance of electronic devices, especially in industrial environments where high levels of electromagnetic activity are present. For projects that involve sensitive electronics, choosing an enclosure with built-in EMI shielding is critical.

Metal enclosures naturally provide excellent EMI shielding, as they block electromagnetic waves from interfering with the device’s operation. In addition, some plastic enclosures are coated with conductive materials to achieve a similar effect. These enclosures are essential for applications like medical devices, communication equipment, and sensitive industrial electronics.

6. Ventilated Enclosures: Keeping Electronics Cool

Heat management is an important consideration for many electronic devices. If your device generates a lot of heat, an enclosure with built-in ventilation may be necessary to prevent overheating. Ventilated enclosures allow air to circulate, helping to dissipate heat and maintain optimal operating conditions.

In some cases, enclosures may also include fans or other cooling mechanisms to enhance airflow and ensure that sensitive components do not overheat. These types of enclosures are commonly used in power supplies, communication equipment, and other high-performance electronics that require heat management.

Selecting the right electronic enclosure is crucial to the safety, performance, and longevity of your devices. Whether you need a durable metal enclosure for an industrial setting, a lightweight plastic option for consumer electronics, or a customizable enclosure for a specialized project, there is a wide range of options available to suit your needs. By carefully considering factors like material, IP rating, EMI protection, and heat management, you can ensure that your electronics are housed in an enclosure that offers the perfect balance of protection and functionality.

Buy Me A Coffee

The Havok Journal seeks to serve as a voice of the Veteran and First Responder communities through a focus on current affairs and articles of interest to the public in general, and the veteran community in particular. We strive to offer timely, current, and informative content, with the occasional piece focused on entertainment. We are continually expanding and striving to improve the readers’ experience.

© 2026 The Havok Journal

The Havok Journal welcomes re-posting of our original content as long as it is done in compliance with our Terms of Use.