Photo by The New York Public Library on Unsplash

A mission can fall apart for many reasons—bad intel, poor planning, or a failure in leadership. But sometimes, the problem isn’t human. Sometimes, the weak link is mechanical. When a military vehicle grinds to a halt in the middle of a combat zone, or a SWAT team’s breaching tool refuses to function during a high-risk raid, the cause is often the same: hydraulic system failure.

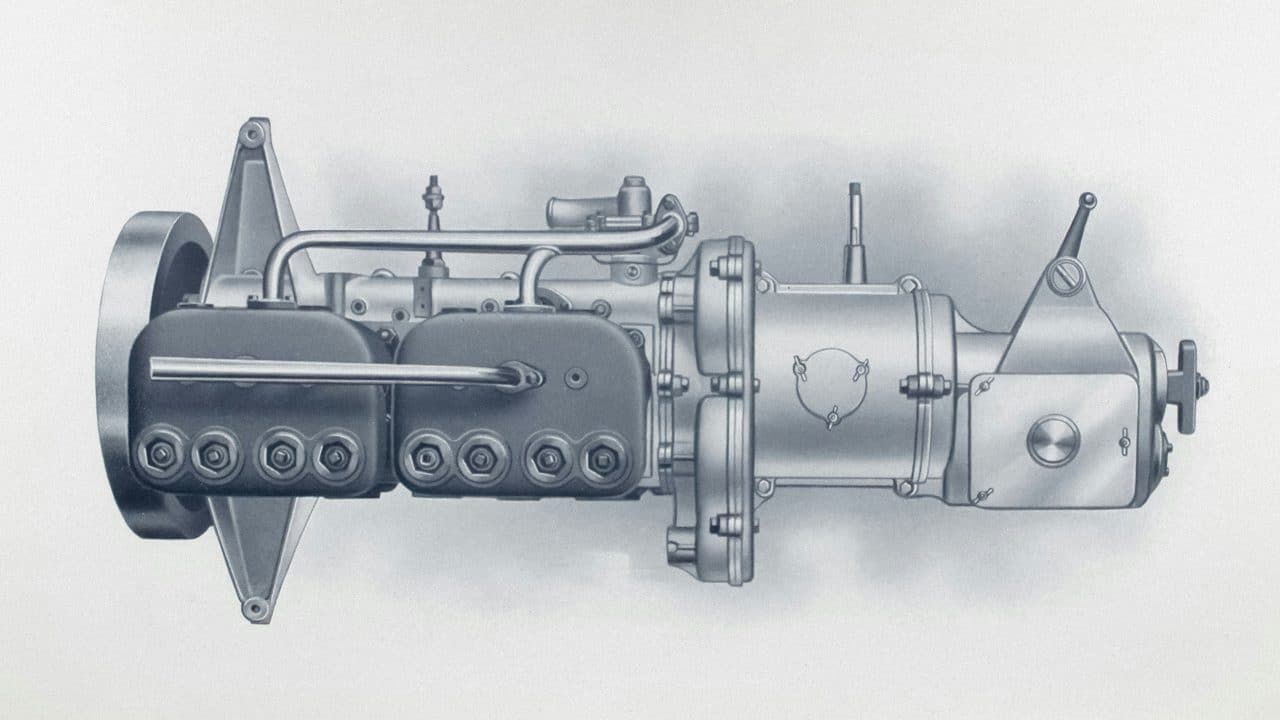

Hydraulics power is one of the most essential tools in military, law enforcement, and emergency response operations. Tanks, aircraft, recovery vehicles, and breaching tools rely on hydraulic pressure to function. When those systems fail, the consequences can be catastrophic. Equipment designed to save lives can become a liability, turning an already dangerous situation into an operational nightmare.

Despite their importance, hydraulic systems are often overlooked until something goes wrong. Neglect leads to breakdowns, breakdowns lead to delays, and in the wrong situation, a delay can be deadly.

How Military and Tactical Teams Rely on Hydraulics

Hydraulics are the backbone of heavy-duty machinery, from the battlefield to urban operations. Without them, tanks wouldn’t roll, aircraft wouldn’t land, and armored breaching tools wouldn’t open the doors standing between operators and their objectives. These systems provide the raw power needed to move multi-ton vehicles, lift heavy loads, and apply precision force in high-stakes scenarios.

Military Vehicles and Aircraft

Tanks like the M1 Abrams depend on hydraulic systems to rotate turrets and stabilize weapons. Armored personnel carriers and recovery vehicles use hydraulic actuators for movement and lifting. Even aircraft—fighters, transport planes, and helicopters—rely on hydraulic pressure for landing gear, flight control surfaces, and braking. A single failure in any of these systems can ground an aircraft or leave a vehicle stranded in enemy territory.

Breaching and Tactical Tools

For special operations forces and SWAT teams, hydraulics provide the muscle behind mission-critical tools. Hydraulic breaching rams allow operators to force open reinforced doors within seconds, while spreaders and cutters—often called the “Jaws of Life”—are essential for vehicle extractions. These tools must work without hesitation. A sluggish or unresponsive hydraulic system during a hostage rescue or high-risk entry can mean the difference between success and failure.

Recovery and Heavy-Lift Operations

When vehicles are disabled in the field, hydraulic-powered recovery vehicles step in to get them moving again. The M88 Hercules, for example, is equipped with hydraulic winches and cranes designed to tow and repair damaged vehicles under fire. Without functioning hydraulics, recovery teams lose their ability to pull assets out of harm’s way, putting more lives and equipment at risk.

The Cost of Hydraulic Failures in Combat and Crisis Scenarios

A mission-critical machine is only as strong as its weakest component. When a hydraulic system fails, the results are often immediate—and disastrous. Military convoys have been stranded mid-mission, aircraft have lost control in the air, and armored vehicles have been left immobile in active war zones, all because of neglected maintenance or undetected hydraulic issues. These failures don’t just put equipment at risk—they put lives on the line.

Breakdowns on the Battlefield

During the Iraq War, several M2 Bradley Fighting Vehicles experienced turret malfunctions due to hydraulic leaks. Without the ability to rotate their cannons, crews were left vulnerable in combat, forced to maneuver entire vehicles just to aim their weapons. Similar issues have plagued other armored vehicles, proving that a single hydraulic failure can cripple a machine designed for war.

In 2010, a CH-53E Super Stallion helicopter crashed off the coast of Afghanistan due to a hydraulic system malfunction, killing several Marines on board. Post-crash investigations revealed that the failure could have been prevented with earlier detection and maintenance.

Tactical Failures in Law Enforcement and Emergency Response

SWAT teams and emergency responders face their own risks when hydraulic tools fail in high-pressure situations. A malfunctioning hydraulic breaching ram can delay entry during an active shooter response, costing precious seconds when lives are at stake. Likewise, fire departments rely on hydraulic-powered rescue tools to extricate crash victims from vehicles. If those tools fail due to poor maintenance, first responders may find themselves helpless when every second counts.

Preventing Catastrophic Failures Through Proactive Maintenance

Hydraulic systems don’t fail without warning—there are always signs. Slow response times, unusual noises, and leaking hydraulic fluid are all indicators that a system is on the verge of breaking down. Ignoring these warnings can turn a routine operation into a crisis.

The U.S. Army Safety Center has repeatedly warned that poor maintenance is a leading cause of vehicle malfunctions, mission failures, and even fatal accidents. Their safety reports highlight how fluid leaks, low-pressure hydraulic systems, and worn-out seals contribute to equipment breakdowns that leave vehicles inoperable at critical moments. To minimize these risks, the military enforces strict maintenance standards for government vehicles, emphasizing the importance of routine inspections and immediate repairs.

Ignoring a failing cylinder might not seem urgent—until it locks up mid-mission and leaves you stranded. That’s why routine hydraulic cylinder repair is a non-negotiable part of keeping mission-critical equipment operational.

Final Thoughts

Missions don’t fail in an instant—they fail because of the small things that go unnoticed until it’s too late. A leaking hydraulic line, a weakened cylinder, or a skipped inspection may not seem like a big deal at first, but in the field, those oversights can lead to vehicles breaking down, weapons systems failing, and life-saving tools becoming useless when they’re needed most.

Ignoring maintenance isn’t just a logistical issue—it’s a risk that can cost lives. Proper hydraulic system upkeep is essential to keeping mission-critical equipment running under pressure, whether in military operations, law enforcement, or emergency response. Veterans, mechanics, and tactical professionals who understand the stakes know that when it comes to hydraulics, you don’t wait for failure—you prevent it.

Preventive maintenance has always been essential for equipment reliability, but evolving technology is transforming military logistics. AI-driven automation is now reshaping supply chains, improving efficiency, and strengthening combat readiness.

Buy Me A Coffee

The Havok Journal seeks to serve as a voice of the Veteran and First Responder communities through a focus on current affairs and articles of interest to the public in general, and the veteran community in particular. We strive to offer timely, current, and informative content, with the occasional piece focused on entertainment. We are continually expanding and striving to improve the readers’ experience.

© 2025 The Havok Journal

The Havok Journal welcomes re-posting of our original content as long as it is done in compliance with our Terms of Use.