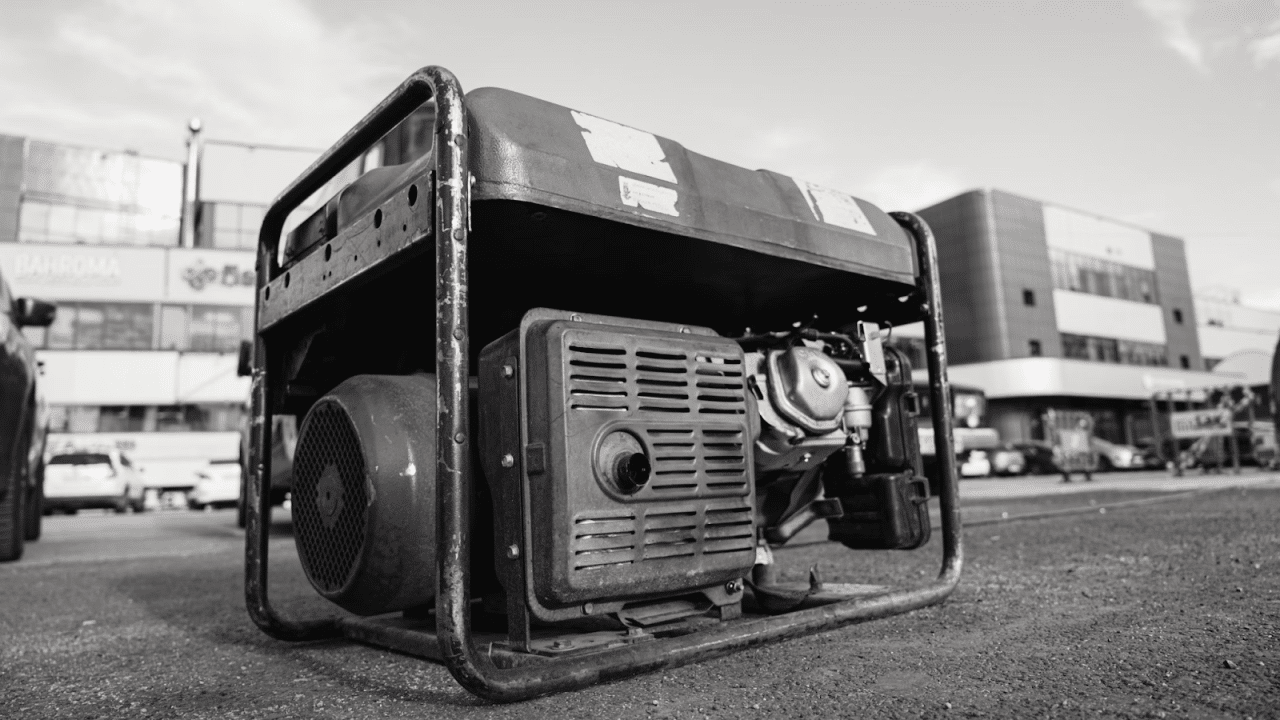

Generator maintenance is crucial for ensuring optimal performance and longevity of industrial equipment. One of the key components of any generator is its bearings, which facilitate smooth operation and minimize friction. Regular maintenance of these components can prevent costly breakdowns and enhance overall efficiency. Let’s explore the fundamentals of generator bearing maintenance, including common challenges, preventative measures, and best practices.

Understanding Generator Bearings

At the heart of every generator lies a series of bearings that support the rotor assembly. These bearings are responsible for maintaining the position of the rotor and allowing it to spin freely. Without proper functioning bearings, the generator can suffer from increased wear and tear, vibrations, and alignment issues. It is essential to understand that there are different types of bearings, including sleeve bearings and rolling-element bearings. Each type has its own maintenance requirements and specific characteristics that cater to different operational needs.

The Importance of Regular Inspections

Routine inspections play a critical role in identifying potential issues before they escalate into major problems. Regular checks can help detect signs of wear, such as discoloration, excessive play, or unusual noises. A thorough inspection involves assessing the bearing housing, checking for proper lubrication, and analyzing temperature variations. Inspections should ideally be performed every few months, depending on the operational environment and frequency of use. Clearly, the success of generator operations hinges on ensuring that all components, particularly the ball bearings, are in optimal condition. By addressing minor issues early through routine inspections, you can significantly extend the lifespan of your generator and minimize costly repairs down the line.

Lubrication Best Practices

One of the most important aspects of bearing maintenance is ensuring proper lubrication. Bearings need the right amount of lubricant to minimize friction and wear. Too much lubrication can lead to overheating, while too little can cause premature failure. It is essential to use a lubricant compatible with the bearing material and operational conditions. Manufacturers often provide specific recommendations for lubrication intervals and types. Assessing the lubricant’s condition during routine inspections is also vital, as contaminants can compromise bearing performance.

Common Challenges in Bearing Maintenance

Despite best efforts, several challenges persist in maintaining generator bearings. Environmental factors such as temperature and humidity can impact bearing performance. Dust and debris can also enter the bearing housing if adequate sealing is not in place, leading to accelerated wear. Furthermore, improper installation can result in misalignment, causing the bearings to function inefficiently. Creating a robust maintenance plan that includes employee training can mitigate these issues and enhance overall equipment reliability.

Replacement Procedures

When a bearing becomes damaged or worn beyond repair, timely replacement is essential. The process involves thorough cleaning of the bearing housing, proper alignment of the new bearing, and ensuring that lubrication is correctly applied. During replacement, it is vital to handle all components carefully to avoid introducing contaminants. Thorough knowledge of the manufacturer’s specifications and a detailed understanding of the generator design will help ensure that replacement bearings perform optimally. By adhering to these procedures, you can guarantee the efficiency and reliability of your generators.

Effective generator bearing maintenance is a comprehensive process requiring attention to detail, regular inspections, and proper lubrication practices. By understanding the importance of bearings in generator performance, identifying common challenges, and implementing best practices, operators can keep their generators running smoothly.

Buy Me A Coffee

The Havok Journal seeks to serve as a voice of the Veteran and First Responder communities through a focus on current affairs and articles of interest to the public in general, and the veteran community in particular. We strive to offer timely, current, and informative content, with the occasional piece focused on entertainment. We are continually expanding and striving to improve the readers’ experience.

© 2026 The Havok Journal

The Havok Journal welcomes re-posting of our original content as long as it is done in compliance with our Terms of Use.